RFID-enabled High Density Racks Improves Productivity in Cold Store Warehouse

Indonesia based Ng Ai Muslim Poultry Industries leverages on Mutual Synergy UHF RFID technology to improve warehouse operations. This hands-free system gives 100% visibility into warehouse inventory; helping to increase traceability, improve movement and loss prevention.

Our RFID Solution delivers

- 100% Warehouse inventory visibility, allowing for more robust operation procedures.

- Automated Forklift Management through RFID, removing reliance on operators manually updating of pallets and inventory location.

- Real-time update within 10 seconds of read, allowing for improved decision making.

Challenge

In order to improve inventory accuracy and on-shelf availability of products, Ng Ai explored the possibility of implementing a RFID system for improved productivity. Ng Ai initially wanted an Enterprise Resource Planning (ERP) system to improve business. After two months, Ng Ai decided that a total RFID-enabled warehouse monitoring solution would be more beneficial to the company, as it would allow operators and management to prevent loss of items and provide real-time visibility of inventory.

Ng Ai chose Mutual Synergy' Warehouse Inventory and Rack Management Solution because of their expertise in Inventory, Forklift and Rack Management. The RFID solution is also able to integrate with the ERP system for real-time updating inventory level and warehouse data. However, another challenge was the operating environment, which can dip to a low of -24 degree Celsius and would require all RFID devices (Terminal, Reader, Antenna and Tags) installed to work with condensation.

The Mutual Synergy' Warehouse Inventory and Rack Management Solution has not only delivered, but also exceeded the expectation of Ng Ai. With RFID-enabled Forklifts, operators can now work in a fully automated environment with full visibility of inventory. The accuracy of reads is as good as, if not better, than that of hand held readers, is in real-time and requires less work. This unlocks a wealth of possibilities in Mutual Synergy' roadmap towards robust operation procedures for our customers.

How It Works

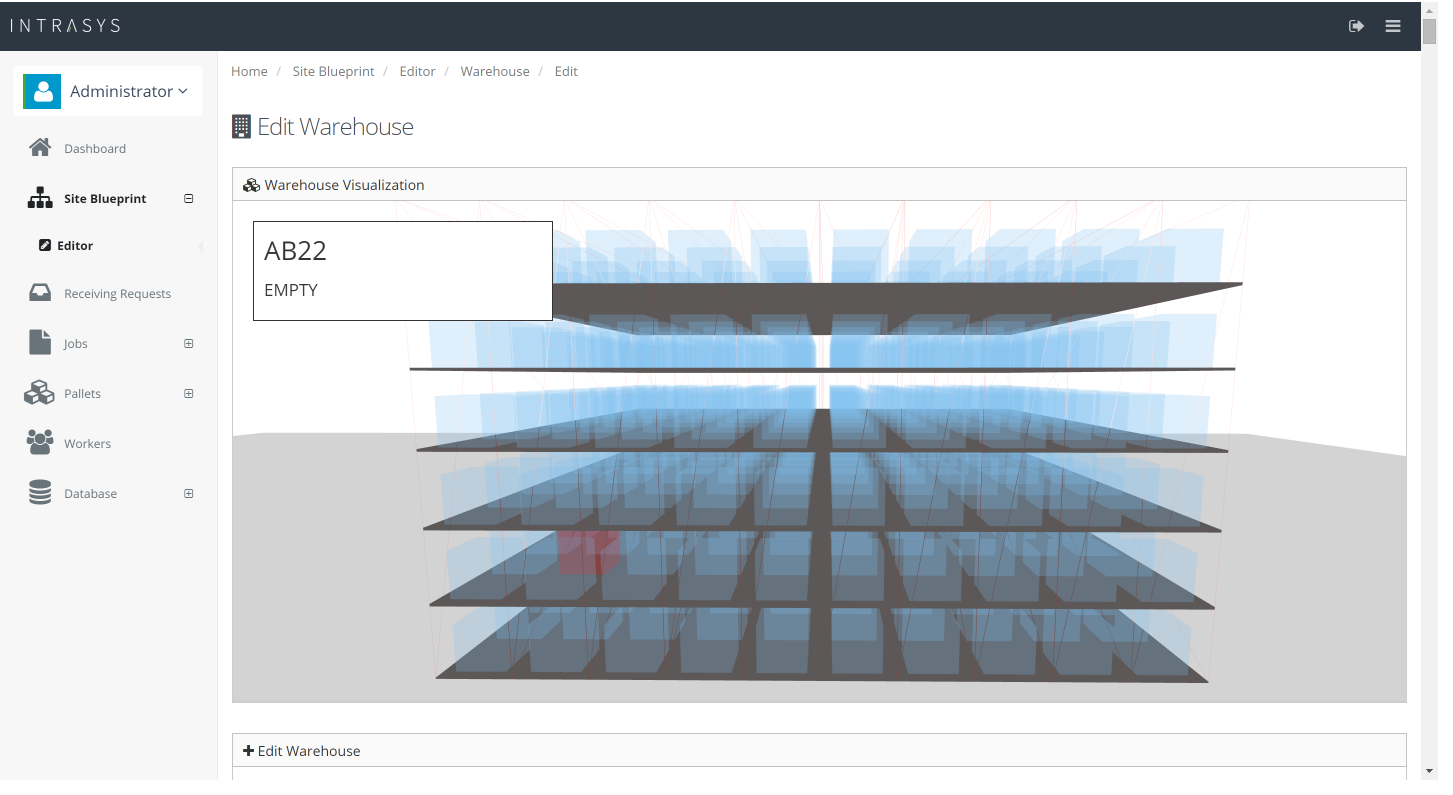

The Ng Ai Warehouse has 2 forklifts that are equipped with 4 RFID antennas at its plate. The antennas are positioned strategically to cater for pallet and rack layout. The RFID Reader is mounted onto the forklift itself, together with a specialized terminal that taps power from the forklift’s power source to create a complete system on the Forklift. All cabling are neatly sorted and in place with existing Forklift cabling setup to minimize infrastructural and power requirements.

All Ng Ai pallets are tagged with Mutual Synergy' Pallet Tags, powered by Impinj Monza chips. Up to 500 pallets are tagged and monitored via RFID antennas and readers on the Forklift. On picking up of a pallet, data from the reader is transferred to the RFID System to provide real-time feedback on the pallet information. After all pick up requests, the data is transferred to the ERP system to register the job as complete.

Ng Ai is now able to continually monitor pallets in their warehouse. This helps both operators and management to easily locate pallets and inventory, and gives management additional information that can be used in conjunction with ERP system to provide useful analytics. The RFID system also improves security by implementing accountability in each action taken automatically. For example, the management would be able to see the last known location of a missing pallet, and who was involved in the action.

Benefits

Second, management now has 100% visibility of the warehouse. Once the forklift is lifting a pallet up, the item movement is tracked in real-time, to the location of the warehouse rack.

Operators and employees are able to easily locate items, and management is able to have accurate, real-time information on warehouse inventory, all the while expending less time and effort looking for and inventorying items. This complete warehouse visibility helps prevent costly mistakes, improves ability to find inventory, and provide useful data to allow management to optimize the warehouse process.

Due to the success of the Mutual Synergy' Inventory and Rack Management Solution, Ng Ai is considering to deploy the same setup for its future warehouses.

Recent Posts

- Real-time Location System (RTLS) for Personnel Tracking in vehicles

Sembcorp - Leading retail apparel Paul Frank Indonesia implements RFID for Inventory

Paul Frank - RFID-enabled High Density Racks Improves Productivity in Cold Store Warehouse

Ng Ai Muslim Poultry - Cold Storage Indonesia RFID Trial

Cold Storage - NRC enhances RFID environment in Indonesia

NRC Indonesia - New RFID system to reduces waiting times at Indonesia Cancer Centre

Indonesia Cancer Centre - SMES and A*STAR collaborate on RFID Solutions

SME AStar Indonesia - Companies that took RFID leap with IDA initiative

IDA Indonesia